Cheese production archives: Difference between revisions

| Line 101: | Line 101: | ||

! Milk origin !! Milk processing and curdling !! Culture input !! Molding !! Ripening time and process | ! Milk origin !! Milk processing and curdling !! Culture input !! Molding !! Ripening time and process | ||

|- | |- | ||

| Cow full milk, unpasteurised, provided by Hoeve de Koeberg<ref name=koeberg>“<i>Organic dairy farm De Koeberg is run by René and Claudia and has 65 dairy cows and about 40 young stock. […] The calves walk in the herd of their mothers for ± 2 months. Then they meet in age groups. When they are ± 1.5 years old they are inseminated. After 9 months they have their first calf and start giving milk. Before they calve, they return to the large herd. We have 60 hectares of land in use. Part of it is for grazing and the rest we grow our own feed for the cows (grass, maize and grain). Our cows spend more than 200 days a year in the pasture. In the winter period they lie comfortably in the straw in the stable. We milk the cows every day around 7 a.m. and 6 p.m., 365 days a year. The organic branch of Friesland-Campina comes to collect the milk every 3 days and makes organic products from it.</i>” (Translated from [https://dekoeberg.com/ Hoeve de Koeberg website]) By bike, it takes 7km to reach the farm, then 11km to reach the Jan Van Eyck Academie and store the 8L of milk before to process it (See one of Robin’s [https://www.strava.com/activities/4279276251 morning ride] on Strava).</ref>, an organic farm based next to Sint Geertruid village. || - Liquid animal rennet<ref name="rennet" /> in heated milk (30-35°C). <br />- 1h curdling before cutting the curds in 2cm cubes. <br />- Let sit 30min at same temperature. || Mesophilic lactic ferments<ref name=lactic>Danisco CHOOZIT MA4002 LYO 5 DCU.</ref> and <i>Geotrichum</i> | | Cow full milk, unpasteurised, provided by Hoeve de Koeberg<ref name=koeberg>“<i>Organic dairy farm De Koeberg is run by René and Claudia and has 65 dairy cows and about 40 young stock. […] The calves walk in the herd of their mothers for ± 2 months. Then they meet in age groups. When they are ± 1.5 years old they are inseminated. After 9 months they have their first calf and start giving milk. Before they calve, they return to the large herd. We have 60 hectares of land in use. Part of it is for grazing and the rest we grow our own feed for the cows (grass, maize and grain). Our cows spend more than 200 days a year in the pasture. In the winter period they lie comfortably in the straw in the stable. We milk the cows every day around 7 a.m. and 6 p.m., 365 days a year. The organic branch of Friesland-Campina comes to collect the milk every 3 days and makes organic products from it.</i>” (Translated from [https://dekoeberg.com/ Hoeve de Koeberg website]) By bike, it takes 7km to reach the farm, then 11km to reach the Jan Van Eyck Academie and store the 8L of milk before to process it (See one of Robin’s [https://www.strava.com/activities/4279276251 morning ride] on Strava).</ref>, an organic farm based next to Sint Geertruid village. || - Liquid animal rennet<ref name="rennet" /> in heated milk (30-35°C). <br />- 1h curdling before cutting the curds in 2cm cubes. <br />- Let sit 30min at same temperature. || Mesophilic lactic ferments<ref name=lactic>Danisco CHOOZIT MA4002 LYO 5 DCU.</ref> and <i>Geotrichum</i>/<i>Brevibacterium</i> culture<ref name=mixedrind>Danisco CHOOZIT PLA mixed rind blend.</ref>. || Brick and pyramid small plastic baskets and cheesecloth. Unpressed. Unmolded after . || - Dry salting on both sides after unmolding and stored on a bamboo mat in a closed box. <br/>- Turned daily while cleaning the whey in the box (to keep humidity at constant level) the first week. <br/>- 1 more week of ripening without any mat in the cheese box. | ||

|} | |} | ||

The cut curds were overcooked, resulting on an elastic texture. The cheeses were unmolded too early: as they were still soft, their shapes loosen up with softer edges — as a Reblochon cheese will do. A solid white rind developed, and it was decided not to wash the cheese as in the Limburger recipe followed; but rather keep it Reblochon-like. When cut, the soft elastic paste wasn’t runny nor grainy. Taste wise, it was pretty close to a young Reblochon: a full milk tone followed by a nutty aftertaste. | The cut curds were overcooked, resulting on an elastic texture. The cheeses were unmolded too early: as they were still soft, their shapes loosen up with softer edges — as a Reblochon cheese will do. A solid white rind developed, and it was decided not to wash the cheese as in the Limburger recipe followed; but rather keep it Reblochon-like. When cut, the soft elastic paste wasn’t runny nor grainy. Taste wise, it was pretty close to a young Reblochon: a full milk tone followed by a nutty aftertaste. | ||

Revision as of 13:07, 22 January 2021

September 2019 | Normandie smoked cheese in Paris

Rygeost cheeses

| Milk origin | Milk processing and curdling | Culture input | Molding | Ripening time and process |

|---|---|---|---|---|

| Normandie full cow milk, unpasteurized. | Powdered animal rennet[1] in heated milk (30-35°C), 24h curdling. | No lactic ferments nor starter culture. | Homemade molds from drilled plastic containers where the cheeses spent a few days without being pressed. | - Turned daily the first week. - 2 days outside in an aerated box before dry salting on both faces. - 4 days in fridge before smoking for 1 hour with hay. - Kept in fridge 1 more week before serving (2 months for extra batch). |

This cheese recipe was inspired by a Danish smoked cheese called Rygeost. It is crucial to let the cheese rest at least one week after smoking, so that the burnt taste does not take over on the freshness of the soft cheese taste. The cheese should not be over-ripen, but it can be kept in the fridge for 2 weeks as the smoke prevents mold to develop on its rind. 2 batches of this cheese were made in Paris before to be served in Amsterdam on the 4th of October for a performance dinner called The Soft Protest, re-chewing & Digest. A third batch was kept unsmoked and ripen for 2 month.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

February 2020 | Vexin cheeses in Paris

Soft blue cheese attempt

| Milk origin | Milk processing and curdling | Culture input | Molding | Ripening time and process |

|---|---|---|---|---|

| Vexin full cow milk, unpasteurized. (Sourced from Laiterie de la Chapelle, Paris.) | Powdered animal rennet[1] in heated milk (30-35°C), 24h curdling. | No lactic ferments. Attempt of starter culture transplantation from blue cheese (Penicillium roqueforti) on the squarish ones. | Homemade molds from drilled plastic containers where the cheeses spent a few days without being pressed. | - Turned daily the first week. - 3 days outside in aerated box before dry salting on both faces. - Sealed in aluminium paper. - 1 month ripening in fridge for 1 round sample. 3 months for the others. |

On the round ones, no small organism culture of any kind was added. The squarish ones saw their milk curdle with Penicillium roqueforti in it (bits of Bleu d'Auvergne AOC cheese in the milk). After being forgotten during the covid19 lockdown in France for 3 months, they gave the most unexpected results. Despite the aluminium paper in which they were sealed, the humid environment led mold develop itself to a much too large extent. As a result, the over-ripen round samples turned out to taste even more “blue-cheese-like” than the squarish ones. Furthermore, none of them develop the expected blue veins but rather spots of unwanted dark mold. On the positive side, both had a grainy/smooth texture akin to Roquefort cheese. Their smell and taste was strong but deliciously tart.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Vexin-cheeses ripen 2.jpg

- Error creating thumbnail: File missing

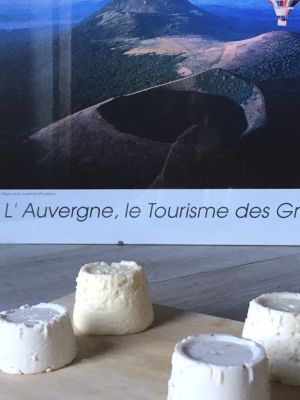

April-May 2020 | Mont-Dore and experimental cheeses in La Bourboule

Mont-Dore cheeses

| Milk origin | Milk processing and curdling | Culture input | Molding | Ripening time and process |

|---|---|---|---|---|

| Cow full milk, unpasteurised, provided by Farm of Ondet corner, in the mountains of Mont-Dore, France. | Powdered animal rennet[1] in heated milk (30-35°C), 24h curdling. | No lactic ferments nor starter culture. | Medium plastic molds from faisselle yogurt and cheesecloth. Softly pressed with a glass of water for a few hours, on both sides. | - Dry salting on both sides after unmolding. - Turned daily the first week. - 10 days of ripening on a wooden board, in an aerated cheese box with a piece of beech timber found in the forest. |

During our quarantine in the French region of Auvergne, we found some time to produce a few cheeses, made from a local milk produced by cows grazing on wild crops found at high altitude. Among them, the Alpine fennel (Meum athamanticum), Cow parsley (Anthriscus sylvestris) and Great yellow gentian (Gentiana lutea). These cheeses have a strong smell, intensively “farm-like”. However their flavor has a certain creaminess, close to a French Saint-Marcellin, though with a firmer texture.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

For the following cheeses, we initiated a quest for types of “cheeses” that could help reducing milk consumption and intensive milk-farms in regions where the landscape is not well-suited for having cows on grass, in landscapes with less sun where beans would thrive, or in sandy, loamy and rocky soils which makes beans quite resilient.

Bean-cheeses

| Milk origin | Milk processing and curdling | Culture input | Molding | Ripening time and process |

|---|---|---|---|---|

| Beans grown in Europe: cooked, hulled and mashed for white and red; heated milk for soja. | Cider vinegar from France. | No lactic ferments nor starter culture. | Small plastic molds from faisselle yogurt, where the cheeses spent a few days without being pressed. | - First tasting after 3 days outside in molds (covered with net). - Second tasting after 18 days of ripening in fridge. |

Hypothesis

The first experiment, “bean-cheese”, is meant to allow cheesemakers to swipe dairy-cheese for vegetal-cheese with the same tools and fungi they use. Thus, they could adapt in time of drought, and benefit from that possible vegetal asset which could attract a different customer (lactose intolerant/vegans) base to their cheesemaking business. As beans (such as soja) have an amazing diversity and can be grown all around the world and dried, each vegetal cheese can be as rooted in its region as the actual cheeses are, with their own microflora and ripening time (like different tofus in China).

Results

The“bean-cheeses” using soja were inspired by “stinky tofu” recipes, but this method turned inefficient when applied to other types of beans (red & white). We did not find any appropriate way to curdle the milk, and focused on bean paste. The taste was strongly vegetal before ripening, and uneatable after 2 weeks — while matured tofu developed strong cheese-like notes.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Potato-cheeses

| Milk origin | Milk processing and curdling | Culture input | Molding | Ripening time and process |

|---|---|---|---|---|

| Cow full milk, unpasteurised, provided by Farm of Ondet corner, in the mountains of Mont-Dore, France. | Cider vinegar from France. | No lactic ferments nor starter culture. Cooked and mashed potatoes was added to the cheese. | Small plastic molds from faisselle yogurt, where the cheeses spent a few days without being pressed. | - First tasting after 3 days outside in molds (covered with net). - Second tasting after 18 days of ripening in fridge. |

Hypothesis

The second —yet unsuccessful— experiment, explores how “potato-cheeses” could be an interesting way to lower pressure on grasslands or imported feed in times of drought, by using ¼ to ½ less milk per cheese produced. While reading about potatoes for various projects, we came across an experiment made by a German cheesemaker, who tried to create cheeses made of mashed potatoes matured with curd (preferably goat or sheep milk). French scholar Louis de Jaucourt, the most prolific contributor to the first Encyclopedia (XVIIIth century), wrote that the share of milk and potatoes could differ depending on customers wealth: the wealthier the milkier.(We repeated the “potato-cheese” process with tofu to give it a try.)

Results

The “potato-cheeses” taste was close to so-called Aligot (a french specialty from Auvergne region) in the first days. It turned to a running paste in the long run, so rope was winded onto each cheese. However, the 2 weeks matured potato brought strong amonia notes that made it uneatable.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

October-November 2020 | Sint Gertruuid cheeses in Maastricht

When joining the Jan Van Eyck Academie and its Food Lab in Maastricht; our initiative for the first months of the residency was to learn, with the help of industrial ferments (Danisco) and Gavin Webber’s recipes, the behaving of the 5 basic microbes used in cheese production:

- Starter cultures including lactic ferments (Lactococcus, Streptococcus thermophilus, etc.)

- Geotrichum candidum

- Penicillium candidum (camemberti or roqueforti)

- Brevibacterium linens

Geotrichum (mold form) cheeses

| Milk origin | Milk processing and curdling | Culture input | Molding | Ripening time and process |

|---|---|---|---|---|

| Cow full milk, unpasteurised, provided by Hoeve de Koeberg[2], an organic farm based next to Sint Geertruid village. | - Liquid animal rennet[1] in heated milk (30-35°C). - 1h curdling before cutting the curds in 2cm cubes. - Let sit 30min at same temperature. |

Mesophilic lactic ferments[3] and Geotrichum/Brevibacterium culture[4]. | Brick and pyramid small plastic baskets and cheesecloth. Unpressed. Unmolded after . | - Dry salting on both sides after unmolding and stored on a bamboo mat in a closed box. - Turned daily while cleaning the whey in the box (to keep humidity at constant level) the first week. - 1 more week of ripening without any mat in the cheese box. |

The cut curds were overcooked, resulting on an elastic texture. The cheeses were unmolded too early: as they were still soft, their shapes loosen up with softer edges — as a Reblochon cheese will do. A solid white rind developed, and it was decided not to wash the cheese as in the Limburger recipe followed; but rather keep it Reblochon-like. When cut, the soft elastic paste wasn’t runny nor grainy. Taste wise, it was pretty close to a young Reblochon: a full milk tone followed by a nutty aftertaste.

- Error creating thumbnail: File missing

- Geotrichum-yeast cheeses unmolding.jpg

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Geotrichum (yeast form) cheeses

| Milk origin | Milk processing and curdling | Culture input | Molding | Ripening time and process |

|---|---|---|---|---|

| Cow full milk, unpasteurised, provided by Hoeve de Koeberg[2], an organic farm based next to Sint Geertruid village. | - Liquid animal rennet[1] in heated milk (30-35°C). - 1h curdling before cutting the curds in 2cm cubes. - Let sit 30min at same temperature. |

No lactic ferments nor starter culture. | Medium plastic molds from faisselle yogurt and cheesecloth. Softly pressed with a glass of water for a few hours, on both sides. | - Dry salting on both sides after unmolding. - Turned daily the first week. - 10 days of ripening on a wooden board, in an aerated cheese box with a piece of beech timber found in the forest. |

Text.

- .jpg

- .jpg

- .jpg

name

| Milk origin | Milk processing and curdling | Culture input | Molding | Ripening time and process |

|---|---|---|---|---|

| Cow full milk, unpasteurised, provided by Hoeve de Koeberg[2], an organic farm based next to Sint Geertruid village. | - Liquid animal rennet[1] in heated milk (30-35°C). - 1h curdling before cutting the curds in 2cm cubes. - Let sit 30min at same temperature. |

No lactic ferments nor starter culture. | Medium plastic molds from faisselle yogurt and cheesecloth. Softly pressed with a glass of water for a few hours, on both sides. | - Dry salting on both sides after unmolding. - Turned daily the first week. - 10 days of ripening on a wooden board, in an aerated cheese box with a piece of beech timber found in the forest. |

Text.

- .jpg

- .jpg

- .jpg

Notes

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 Calves (cows offsprings) stomach extract used as a coagulant in traditional cheesemaking.

- ↑ 2.0 2.1 2.2 “Organic dairy farm De Koeberg is run by René and Claudia and has 65 dairy cows and about 40 young stock. […] The calves walk in the herd of their mothers for ± 2 months. Then they meet in age groups. When they are ± 1.5 years old they are inseminated. After 9 months they have their first calf and start giving milk. Before they calve, they return to the large herd. We have 60 hectares of land in use. Part of it is for grazing and the rest we grow our own feed for the cows (grass, maize and grain). Our cows spend more than 200 days a year in the pasture. In the winter period they lie comfortably in the straw in the stable. We milk the cows every day around 7 a.m. and 6 p.m., 365 days a year. The organic branch of Friesland-Campina comes to collect the milk every 3 days and makes organic products from it.” (Translated from Hoeve de Koeberg website) By bike, it takes 7km to reach the farm, then 11km to reach the Jan Van Eyck Academie and store the 8L of milk before to process it (See one of Robin’s morning ride on Strava).

- ↑ Danisco CHOOZIT MA4002 LYO 5 DCU.

- ↑ Danisco CHOOZIT PLA mixed rind blend.