Cheese production archives: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

==June 2021 | Four horizons of Ardennes’ milk | ==June 2021 | Four horizons of Ardennes’ milk== | ||

to come | |||

==April 2021 | Ardennes cheeses in Maastricht== | ==April 2021 | Ardennes cheeses in Maastricht== | ||

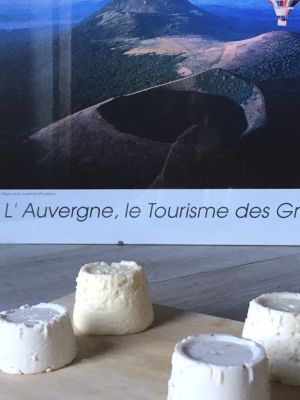

[[File:Geotrichum-yeast_cheeses_serving.jpg|thumb|Thumbnailed image|To fill.]] | [[File:Geotrichum-yeast_cheeses_serving.jpg|thumb|Thumbnailed image|To fill.]] | ||

<b>After gaining experience with the use of industrial ferments to make cheese with the milk from Hoeve de Koeberg<ref name=koeberg>, Robin Bantigny initiated a 1 month performance consisting on a daily routine consisting of: | <b>After gaining experience with the use of industrial ferments to make cheese with the milk from Hoeve de Koeberg<ref name="koeberg" />, Robin Bantigny initiated a 1 month performance consisting on a daily routine consisting of: | ||

# Cycling errands for milk in 4 differents dairy farms, | # Cycling errands for milk in 4 differents dairy farms, | ||

# Cheese making in the Food Lab of the Jan van Eyck Academie, | # Cheese making in the Food Lab of the Jan van Eyck Academie, | ||

Revision as of 17:07, 2 July 2021

June 2021 | Four horizons of Ardennes’ milk

to come

April 2021 | Ardennes cheeses in Maastricht

After gaining experience with the use of industrial ferments to make cheese with the milk from Hoeve de Koeberg[1], Robin Bantigny initiated a 1 month performance consisting on a daily routine consisting of:

- Cycling errands for milk in 4 differents dairy farms,

- Cheese making in the Food Lab of the Jan van Eyck Academie,

- Soil analysis of local pastures’ biotope.

This performance roughly named [Landscape, Soil, Cheese and me] brought Robin to experiment even more on cheese-making, drived only by his feelings of deep entanglement with the landscape surrounding him and the other artists staying at the Jan van Eyck Academie — to whom the cheeses were destinated to.

Organic goat milk, batch #1 | 02.04.2021

| Milk amount/origin and cycling route | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| 8L goat full milk, unpasteurised, provided by Zorgboerderij Ravensbosch[2] Cycling activity of the 01.04.2021. |

No ferments added. | - 5mL liquid animal rennet[3] in heated milk (35°C). - 1.5h curdling. Half of curd cut in small cubes, half poured in cheesecloth with ladle. |

Medium (x2) and small (x2) plastic baskets and cheesecloth. Unpressed and left to drain for 3 days. | - Dry salting on both sides after unmolding. Flipped and store in box in the Mush-room[4]. - Flipped daily for 4 days, with a few dark molds scraped of the surface. - Dark molds were left to grow freely on small pyramide. - Out of box to rest on hay and moistued with whey. - Small round and Medium brique: 20 days of ripening; Medium round: 50 days of ripening; Small square: 45 days of ripening. |

The medium brique and small round were frist eaten, and happen to taste quite mild with a nice aerated texture, rather soft and not too elastic.

The medium round was eaten one month later during the tastings with resident artists, and happen to stay rather mild despite more ageing.

The last small pyramide was eaten one month later, at home with friends: it was covered with a variety of dark molds but happen do be deliciously dry and “goaty” (like an old Bouton de culotte goat cheese). This shows again that free wild molds, even without any control, is one of the conditions for tasty cheeses.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Cow milk, batch #1 | 02.04.2021

| Milk amount/origin and cycling route | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| 7L cow full milk, unpasteurised, provided by Ferme du Temple[5]. Cycling activity of the 02.04.2021. |

No ferments added. | - 5mL liquid animal rennet[3] in heated milk (35°C). - 1h curdling. Curds were cut and cooked while stirring for 30' at 45°C. - Cooked curds were then salted (1tbsp). |

All the curds were put in the big tomme hoop with weight on top to drain. It was then flipped to drain the opposite side. | - The cheese was kept in a box to stay moist. - After 3 days it was salted on both side with coarse sea salt, flipped daily. -Yellow and white Geotrichum appeared 3 days later, and the box was moved to the Mush-room[4]. -After 10 days of ripening, the cheese was put out of the box on hay and moisturised with whey. - 2/4 of the cheese was eaten with friends after a total 1 month of ripening. 1/4 was given to the farmers. - 1/4 was eaten after 50 days. |

The cheese looked a lot like a Reblochon cheese, with nice proportions and smooth texture, as well as a washed out yellow rind. However, the taste was mild and under-salted: it could have ripen even longer.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Organic cow milk, batch #1 | 06.04.2021

| Milk amount/origin and cycling route | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| 8L cow full milk, unpasteurised, provided by Hoeve de Koeberg[1]. Cycling activity of the 05.04.2021. |

1/4tsp Mesophilic lactic ferments[6] and 1/4tsp Penicillium Roqueforti [7]. | - Ferments left to develop for half an hour in heated milk (45°C). - 15mL liquid animal rennet[3] added. - Did not curdle after 1 hour and was left at room temperature for 2 days. |

- The result was a very acidic, aerated agregate of curds. It was drained with cheesecloth in the big tomme hoop, flipped and stored in a box. - After draining for one day, it was salted on both side with coarse sea salt and rubbed in wild garlic leaves, then stored in box in the Mush-room[4]. |

- 5 days after being rubbed, it was put out of the box and covered with aluminium foil, then flipped. - After 25 from production, it was put in fridge. - It was eaten after a total of 50 days of ageing with the resident artists. |

When it was brought out of the wild garlic leaves, a microbial film had covered the now brown leaves. Despite its age, the cheese was still looking white and soft like a recently made cheese. The taste was interesting, with fresh unsalted goat cheese vibes and off-flavors of wild garlic. It was very appreciated by residents.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Goat milk, batch #1 | 08.04.2021

| Milk amount/origin and cycling route | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| 4L goat full milk, unpasteurised, provided by Melkgeitenbedrijf Noelmans-Peters[8]. Cycling activity of the 07.04.2021. |

1/8tsp Penicillium Roqueforti [7]. | - Ferments left to develop for half an hour in heated milk (35°C). - 4mL liquid animal rennet[3] in heated milk (35°C). - 1h and 20' curdling. Curds were cut and cooked while stirring for 20' at 40°C. |

All the curds were put in a cylindric container with some whey to aggregate. | - After 3 days in the container, a nice cheese full of holes was obtained. It was salted on both side with 1/4tsp of sea salt and stored in a box. - After 4 days flipped daily, blue mold was growing well. It was salted again (1/2tsp) and covered with alumonium foil and put in the Mush-room[4] out of the box. - 1 week later it was out of aluminium foil, with alot of blue and green P. Roqueforti growing on the aerated side. It was eaten with resident artists on the next day, after 23 days of ripening. |

The container-molding technic developed from the last cow cheese “failure” was one point to obtain a cheese which meat is aerated enough to host P. Roqueforti.

The cheese obtained was rather creamy with light tones of blue. Fortunately, even “blue-cheese-haters” liked it.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Organic goat milk, batch #2 | 08.04.2021

| Milk amount/origin and cycling route | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| 8L goat full milk, unpasteurised, provided by Zorgboerderij Ravensbosch[2]. Cycling activity of the 08.04.2021. |

1/4tsp Penicilium Camemberti[9]. | - Ferments left to develop for half an hour in heated milk (35°C). - 10mL liquid animal rennet[3] in heated milk (35°C). - After 1h20' of curdling, curds were cut roughly. |

- Cut curds were put by hand in medium hoops with cheesecloth and small hoops without cloth. - The 2 cheeses were left to drain inside a box for 1 day. - They ended up having odd shapes: medium round was shaped like a volcano and medium brique was too empty on top so leftover curds added to fill, and they were flipped in cheesecloth and kept in molds. The small ones were put out of their hoops in a box. - The medium round was collapsing and kept in mold for 1 more day. The small cheeses were too collapsed, so Robin crumbled them with 1/4tsp sea salt and back in cheesecloth in the small pyramide hoop. - 3 days after curdling, all cheeses were out of hoops. |

- All of them were salted on both sides with sea salt. -All of them were in the Mush-room[4] 3 days after curdling, flipped daily, and started to develop white P. Camemberti molds. - Medium round and small pyramide: 15 days of ripening; Medium brique: 35 days of ripening. |

The medium round developed good soft bloomy rind flavors, was creamy and runny, but not so strong. It had the most success among resident artists. The small pyramide had soft bloomy rind flavors and farm notes, but crumbly inside.

The medium brique had a good taste, with strong goat character and no difficult or off-flavors, like other over-aged soft cheeses.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Cow milk, batch #2 | 09.04.2021

| Milk amount/origin and cycling route | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| 11L cow full milk, unpasteurised, provided by Ferme du Temple[5]. Cycling activity of the 09.04.2021. |

No ferments added. | - 16mL liquid animal rennet[3] in heated milk (40°C). -1h curdling and 20' of cooking and stirring the curds (45°C). - Curds were ripen in cheesecloth in box with whey for 2 days. |

- Aged curds were drained in a container in the fridge. 11g of finely cut wild garlic and 1tbsp of sea salt was added. Everyhting was mixed by hand and molded in big tomme for 30min with weight, on each side, before to be stored in a box. |

- After one day of ripening, the cheese cracked in 2 pieces and was put back in a hoop in the box. - 2 days later, Robin decided to fill the box of cracked cheese with goat whey (pH4.7) from batch #2 to make cream cheese later. - The curds were mixed by hand with goat cream from batch #3. - 14 days after curdling, the cream-cheese tasted for the first time. |

This wild garlic perfumed cheese failed but turned out to have success among resident artists, despite having a strong Camembert notes soften by its creamy texture and the spicy wild garlic.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Whey transformation #1 | 11.04.2021

1.5 weeks of whey was cooked to a boil, simmer for 30' and drained with cheesecloth and a ladle.

±1.5kg of good white Ricotta (dry curds) was obtained. It was stored in a bucket in the fridge and eaten with all sorts of dishes.

Organic cow milk, batch #2 | 13.04.2021

| Milk amount/origin and cycling route | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| 7L cow full milk, unpasteurised, provided by Hoeve de Koeberg[1]. <https://www.strava.com/activities/5117911752 Cycling activity of the 12.04.2021.] | 1/4tsp Mesophilic[6] and and 1/4tsp Staphylococcus [10]. | - Ferments left to develop for half an hour in heated milk (35°C). - 8mL liquid animal rennet[3] in heated milk (30°C). -After 1h, the curds were cut and left to rest for one day. |

- One day after curdling, curds were put in cheesecloth and moulded in big tomme for 40' with weight, on each sides of the cheese. |

- The cheese was flipped and salted on both sides 3 days after curdling. It was stored in the Mush-room[4]. - After 4 more days, Geotrichum candidum skin was growing well on it. - It was often flipped until it became runny after 25 days of ripening. - Eaten after 36 days of ripening, cut and stored in fridge for later atsting. |

After the 36 days of ripening, the cheese happen to be undersalted and rather mild with slightly off-flavors; with a meat rather hard and dry with a lot of holes. One week in fridge later, flavors improved greatly, becoming close to washed rind cheeses like Pont L'Évèque.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Goat milk, batch #2 + Organic goat milk batch #3 | 16.04.2021

| Milk amount/origin and cycling route | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| - 11L goat full milk, unpasteurised, provided by Melkgeitenbedrijf Noelmans-Peters[8]. Cycling activity of the 14.04.2021. -5L goat organic full milk, unpasteurised, provided by Zorgboerderij Ravensbosch[2]. Cycling activity of the 15.04.2021. |

1/4tsp Penicillium Roqueforti [7]. | - The 11L stood 2 days at room temperature and went too acidic (pH4), with a yogurt texture. <br.>- 5L were less acidic (pH5.3) so the 2 batches were merged. - - Ferment left to develop for half an hour in heated milk (37°C). - 12mL liquid animal rennet[3] in heated milk (30°C). -After 1h, still very acidic and did not curdle more. |

- Add to pass through cheesecloth as for Ricotta to get the curds. - They were salted and put in all hoops available with cheesecloth: medium ones, small ones and big tomme. |

- 2 days later, all cheeses were unmolded but with risks of shrinking down. They were put in boxes and in protective net. - 3 days later, an interesting mix of P. Roqueforti and Geotrichum candidum was growing. However, the rind was fragile and they were all carefully flipped: close to no rind on the other sides of them. - 1 week after unmolding they were too runny with rind slipping from the cheese all over the leaking whey. Big tomme was rubbed in aluminium foil and brought in the Mush-room[4]. Medium tomme was put in plastic film to get to Arvid&Marie dinner (ungraceful looking). Others were kept in opened box in the Mush-room[4] to let them dry slowly. - All except the big tomme were eaten beetween 15 days and 22 days. |

Small and medium ones presented a good strong goat taste brought by the runny rind, although their meat was soft and fresh like Ricotta (typical from cheeses curdled from lactic acidification rather than rennet).

Unfortunately, after 23 days of ripening the big tomme was put out of the aluminium and an unberable pikant taste took over: it was thrown away.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Cow milk, batch #3 | 19.04.2021

| Milk amount/origin and cycling route | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

7L cow full milk, unpasteurised, provided by Ferme du TempleCite error: The opening <ref> tag is malformed or has a bad name. Cycling activity of the 02.04.2021. |

No ferments added. | - 5mL liquid animal rennet[3] in heated milk (35°C). - |

All the curds were put in the big tomme hoop with weight on top to drain. It was then flipped to drain the opposite side. | - - |

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

October-November 2020 | Sint Gertruuid cheeses in Maastricht

When joining the Jan Van Eyck Academie and its Food Lab in Maastricht; Robin’s initiative for the first months of the residency was to learn, with the help of industrial ferments (Danisco) and Gavin Webber’s recipes, the behaving of the 5 basic microbes used in cheese production:

- Starter cultures including lactic ferments (Lactococcus, Streptococcus thermophilus, etc.)

- Geotrichum candidum

- Penicillium candidum (camemberti or roqueforti)

- Brevibacterium linens

Geotrichum (mold form) cheeses | 15th of October

| Milk origin | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| Cow full milk, unpasteurised, provided by Hoeve de Koeberg[1], an organic farm based next to Sint Geertruid village. | Mesophilic lactic ferments[6] and Geotrichum - Brevibacterium culture[11]. | - Liquid animal rennet[3] in heated milk (30-35°C). - 1h curdling before cutting the curds in 2cm cubes. - Let sit 30min at same temperature. |

Brick and pyramid “faisselle” small plastic baskets and cheesecloth. Unpressed. Unmolded after 2 hours. | - Dry salting on both sides after unmolding. Stored on a bamboo mat in a closed box. - Turned daily while cleaning the whey in the box (to keep humidity at constant level) the first week. - 1 more week of ripening without any mat in the cheese box. |

The cut curds were overcooked, resulting on an elastic texture. The cheeses were unmolded too early: as they were still soft, their shapes loosen up with softer edges — as a Reblochon cheese will do. A solid white rind developed, and it was decided not to wash the cheese as in the Limburger recipe followed; but rather keep it Reblochon-like. When cut, the soft elastic paste wasn’t runny nor grainy. Taste wise, it was pretty close to a young Reblochon: a full milk tone followed by a nutty aftertaste.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Geotrichum (yeast form) cheeses | 21th of October

| Milk origin | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| Cow full milk, unpasteurised, provided by Hoeve de Koeberg[1], an organic farm based next to Sint Geertruid village. | Mesophilic lactic ferments[6] and Geotrichum - Brevibacterium culture[11]. | - Liquid animal rennet[3] in heated milk (30-35°C). - 1h curdling before cutting the curds in 2cm cubes. - Let sit 30min at same temperature. |

Small pyramid, Small round and Medium round plastic faisselle molds and cheesecloth. Unpressed. Unmolded after 1 day. | - Dry salting on both sides 2 days after unmolding. Storing on a bamboo mat in a closed box. - Turned daily while cleaning the whey for 8 more days, without any mat in the cheese box. |

As the curds were less cooked thus less prone to stick to each other, the cheeses kept more moisture. The cheeses were kept too long before salting, and as a result, an unwanted Mucor mold[12] grown rapidly (the bamboo mat could be the source of it). The cheeses were brushed to get ride of the hairy mold, and in a matter of days the yellow Geotrichum yeast colonised the rinds. But the damage was done and, although the cheese texture was good (white and grainy inside, runny next to the rind), its taste was slightly putrid on the rind.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Brevibacterium cheeses | 3rd of November

| Milk origin | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| Cow full milk, unpasteurised, provided by Hoeve de Koeberg[1], an organic farm based next to Sint Geertruid village. | Mesophilic lactic ferments[6] and Geotrichum - Brevibacterium culture[11]. | - Liquid animal rennet[3] in heated milk (30-35°C). - 1h curdling before cutting the curds in 2cm cubes. - Let sit 30min at same temperature. |

Big tomme and small round plastic faisselle molds and cheesecloth. Slightly pressed. Unmolded after 1 day. | - Washed for 1h, wiped and flipped every day for 3 days. - Washed for 1h, wiped and flipped every 2 day for 2 weeks. - 20 days in total of ripening in the cheese box, at high moisture. - Covered with active carbon (from coconut husk) a few days before serving. - The big “Tomme” was washed 1 more week and kept 2 more weeks in fridge. |

This was our first experience in washed rind cheeses. Among them, the Herve cheese is typical from the Limburg region. Most washed cheese are found in the North of France, in Belgium and more generally in the wettest European countries. The goal of the brine washing, often mixed with more starter culture, paired with very moist ripening rooms; is to grow a characteristic orange rind resulting from Brevibacterium linens bacterias. Although we did not manage to get it to fully colonise our cheeses, blue-grey and bright yellow spots grown — could be Penicillium and Pseudomas fluorescens microbes. Those spots were scratched and salt was added directly on the rind to get rid of it. The smaller cheese, eaten first, had a semi-hard texture and a discreet taste that came close to washed cheeses. Nevertheless, because it went through more brine baths, the biggest cheese was over-salted — still appreciable with figs jam.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Penicillium camemberti cheeses | 11th of November

| Milk origin | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| Cow full milk, unpasteurised, provided by Hoeve de Koeberg[1], an organic farm based next to Sint Geertruid village. | Geotrichum candidum[13] and Penicillium camemberti culture[9]. | - Liquid animal rennet[3] in heated milk (30-35°C). - 1h curdling, curd directly put in the molds with a ladle. - Let sit 30min at same temperature. |

Big tomme, medium brick and small pyramid plastic molds and cheesecloth. Unpressed. Unmolded after 4 days of draining. | - Dry salting on both sides after unmolding. Storing on plastic racks in an aerated box (to lower moisture). - Turned while cleaning the whey every day for 2 weeks. - Kept 1 week and more in the fridge for a total of ± 3 weeks. |

This was our first experience in bloomy soft cheeses (Brie, Camembert, Neufchâtel). They ask for the use of Penicillium camemberti to obtain a white “bloomy” rind. Instead of cutting the curds as for most cheeses, it has to be put directly in molds with the help of a ladle. Thus, the cheeses obtained are full of water (whey) and need to drain for a few days before to be unmolded. As a result, the cheeses thickness is shrinking drastically, but the inside stays soft. Those cheeses taste was milder than of a Camembert, closer to a Brie. They became runny as expected after some time in the fridge.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Whey vinegars | 11th of November

| Milk origin | Whey origin | Input | Ripening time and process |

|---|---|---|---|

| Cow full milk, unpasteurised, provided by Hoeve de Koeberg[1]. | Penicillium camemberti batch of cheeses. | Beetroot juice. Canne sugar. | 2 months in jars with air-release valves. |

Hypothesis

The main by-product of cheesemaking is whey, or lactoserum. It is often a challenge to find ways to valuate this bulky “leftover” of cheese production, and this is something we already addressed in the article About whey. Our little cheese production is no exception to this issue: what to do with the litters of leftover whey? It appears that there is a wide variety of fermented dairy drinks; and among them some rely on a bend of both whey and milk. Kumis is a beverage from Central Asia traditionally made with mare or donkey’s milk — the available brands are mostly made with cow’s milk today. Although Kumis is similar to kefir, it has the intriguing ability to get slightly alcoholic, thanks to the sucrose added during fermentation.

Results

For all those reasons, we tried to get Kumis out of our leftover whey. On one side with a sweet beetroot juice added to whey, on the other with canne sugar. After 2 months of fermentation in jars, and a few weeks in the fridge, we obtained a good result with the 1st experimentation, that led to something tasting like a beetroot vinegar with a strong Camembert aftertaste. It makes an interesting seasoning, but certainly not a pleasant drink. The 2d experiment was unsuccessful: the refined sugar provided too much sweetness, that matches poorly with the acidic whey. Aside from those 2 experiments, a “witness” simple whey jar aged as long and made up a nice lactic vinegar. Although we did not succeed in making any beverage, those are nice way to use our cheeses’ by-products.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

April-May 2020 | Mont-Dore and experimental cheeses in La Bourboule

Mont-Dore cheeses | 30th of April - 23th of May

| Milk origin | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| Cow full milk, unpasteurised, provided by Farm of Ondet corner, in the mountains of Mont-Dore, France. | No lactic ferments nor starter culture. | Powdered animal rennet[3] in heated milk (30-35°C), 24h curdling. | Medium plastic molds from faisselle yogurt and cheesecloth. Softly pressed with a glass of water for a few hours, on both sides. | - Dry salting on both sides after unmolding. - Turned daily the first week. - 10 days of ripening on a wooden board, in an aerated cheese box with a piece of beech timber found in the forest. |

During our quarantine in the French region of Auvergne, we found some time to produce a few cheeses, made from a local milk produced by cows grazing on wild crops found at high altitude. Among them, the Alpine fennel (Meum athamanticum), Cow parsley (Anthriscus sylvestris) and Great yellow gentian (Gentiana lutea). These cheeses have a strong smell, intensively “farm-like”. However their flavor has a certain creaminess, close to a French Saint-Marcellin, though with a firmer texture.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

For the following cheeses, we initiated a quest for types of “cheeses” that could help reducing milk consumption and intensive milk-farms in regions where the landscape is not well-suited for having cows on grass, in landscapes with less sun where beans would thrive, or in sandy, loamy and rocky soils which makes beans quite resilient.

Bean-cheeses | April 2020

| Milk origin | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| Beans grown in Europe: cooked, hulled and mashed for white and red; heated milk for soja. | No lactic ferments nor starter culture. | Cider vinegar from France. | Small plastic molds from faisselle yogurt, where the cheeses spent a few days without being pressed. | - First tasting after 3 days outside in molds (covered with net). - Second tasting after 18 days of ripening in fridge. |

Hypothesis

The first experiment, “bean-cheese”, is meant to allow cheesemakers to swipe dairy-cheese for vegetal-cheese with the same tools and fungi they use. Thus, they could adapt in time of drought, and benefit from that possible vegetal asset which could attract a different customer (lactose intolerant/vegans) base to their cheesemaking business. As beans (such as soja) have an amazing diversity and can be grown all around the world and dried, each vegetal cheese can be as rooted in its region as the actual cheeses are, with their own microflora and ripening time (like different tofus in China).

Results

The“bean-cheeses” using soja were inspired by “stinky tofu” recipes, but this method turned inefficient when applied to other types of beans (red & white). We did not find any appropriate way to curdle the milk, and focused on bean paste. The taste was strongly vegetal before ripening, and uneatable after 2 weeks — while matured tofu developed strong cheese-like notes.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Potato-cheeses | April 2020

| Milk origin | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| Cow full milk, unpasteurised, provided by Farm of Ondet corner, in the mountains of Mont-Dore, France. | No lactic ferments nor starter culture. | Cider vinegar from France. | Cooked and mashed potatoes were added to the cheese. Small plastic molds from faisselle yogurt, where the cheeses spent a few days without being pressed. | - First tasting after 3 days outside in molds (covered with net). - Second tasting after 18 days of ripening in fridge. |

Hypothesis

The second —yet unsuccessful— experiment, explores how “potato-cheeses” could be an interesting way to lower pressure on grasslands or imported feed in times of drought, by using ¼ to ½ less milk per cheese produced. While reading about potatoes for various projects, we came across an experiment made by a German cheesemaker, who tried to create cheeses made of mashed potatoes matured with curd (preferably goat or sheep milk). French scholar Louis de Jaucourt, the most prolific contributor to the first Encyclopedia (XVIIIth century), wrote that the share of milk and potatoes could differ depending on customers wealth: the wealthier the milkier.(We repeated the “potato-cheese” process with tofu to give it a try.)

Results

The “potato-cheeses” taste was close to so-called Aligot (a french specialty from Auvergne region) in the first days. It turned to a running paste in the long run, so rope was winded onto each cheese. However, the 2 weeks matured potato brought strong amonia notes that made it uneatable.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

February 2020 | Vexin cheeses in Paris

Soft blue cheese attempt

| Milk origin | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| Vexin full cow milk, unpasteurized, from Launay farm[14]. | No lactic ferments. Attempt of starter culture transplantation from blue cheese (Penicillium roqueforti) on the squarish ones. | Powdered animal rennet[3] in heated milk (30-35°C), 24h curdling. | Homemade molds from drilled plastic containers where the cheeses spent a few days without being pressed. | - Turned daily the first week. - 3 days outside in aerated box before dry salting on both faces. - Brie cheese (Penicillium camemberti) rind added on the round ones, then all sealed in aluminium paper. - 1 month ripening in fridge for 1 round sample. 3 months for the others. |

On the round ones, no small organism culture of any kind was added but they aged with bits of bloomy rind (from Brie de Meaux AOC cheese). The squarish ones saw their milk curdle with Penicillium roqueforti in it (bits of Bleu d'Auvergne AOC cheese in the milk). After being forgotten during the covid19 lockdown in France for 3 months, they gave the most unexpected results. Despite the aluminium paper in which they were sealed, the humid environment led mold develop itself to a much too large extent. As a result, the over-ripen round samples turned out to taste even more “blue-cheese-like” than the squarish ones. Furthermore, none of them develop the expected blue veins but rather spots of unwanted dark mold. On the positive side, both had a grainy/smooth texture akin to Roquefort cheese. Their smell and taste was strong but deliciously tart.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

September 2019 | Normandie smoked cheese in Paris

Rygeost cheeses | 11th of September

| Milk origin | Culture input | Milk processing and curdling | Molding process | Ripening time and process |

|---|---|---|---|---|

| Normandie organic full cow milk. Vexin full cow milk, unpasteurized, from Launay farm[14]. | No lactic ferments nor starter culture. | Powdered animal rennet[3] in heated milk (30-35°C), 24h curdling. | Homemade molds from drilled plastic containers where the cheeses spent a few days without being pressed. | - Turned daily the first week. - 2 days outside in an aerated box before dry salting on both faces. - 4 days in fridge before smoking for 1 hour with hay. - Kept in fridge 1 more week before serving (2 months for extra batch). |

This cheese recipe was inspired by a Danish smoked cheese called Rygeost. It is crucial to let the cheese rest at least one week after smoking, so that the burnt taste does not take over on the freshness of the soft cheese taste. The cheese should not be over-ripen, but it can be kept in the fridge for 2 weeks as the smoke prevents mold to develop on its rind. 2 batches of this cheese were made in Paris before to be served in Amsterdam on the 4th of October for a performance dinner called The Soft Protest, re-chewing & Digest. A third batch was kept unsmoked and ripen for 2 month.

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

- Error creating thumbnail: File missing

Notes

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 “Organic dairy farm De Koeberg is run by René and Claudia and has 65 dairy cows and about 40 young stock. […] The calves walk in the herd of their mothers for ± 2 months. Then they meet in age groups. When they are ± 1.5 years old they are inseminated. After 9 months they have their first calf and start giving milk. Before they calve, they return to the large herd. We have 60 hectares of land in use. Part of it is for grazing and the rest we grow our own feed for the cows (grass, maize and grain). Our cows spend more than 200 days a year in the pasture. In the winter period they lie comfortably in the straw in the stable. We milk the cows every day around 7 a.m. and 6 p.m., 365 days a year. The organic branch of Friesland-Campina comes to collect the milk every 3 days and makes organic products from it.” (Translated from Hoeve de Koeberg website) By bike, it takes 7km from Heer neighborhood to reach the farm, then 11km to reach the Jan Van Eyck Academie and store the 8L of milk before to process it (See one of Robin’s morning ride on Strava).

- ↑ 2.0 2.1 2.2 “Since 2011, Maurice and Clemence Dezaire have been offering meaningful daytime activities to the elderly in groups in the only organic dairy goat farm of Limburg. 380 Saanen dairy goats are milked twice a day in a 30-stall milking parlour. Their milk is processed by OGC. The milk is mainly used to produce cheese and milk powder for organic products.” (Translated from Zorgboerderij Ravensbosch website) By bike, it takes 13km from Heer neighborhood to reach the farm, then 17km to reach the Jan Van Eyck Academie and store milk before to process it.

- ↑ 3.00 3.01 3.02 3.03 3.04 3.05 3.06 3.07 3.08 3.09 3.10 3.11 3.12 3.13 3.14 3.15 Calves (cows offsprings) stomach extract used as a coagulant in traditional cheesemaking.

- ↑ 4.0 4.1 4.2 4.3 4.4 4.5 4.6 4.7 Jop Mens built the Mush-room in the Jan van Eyck Academie, in perspective of growing mushrooms in it. Unfortunately, the Covid19 related lockdown made it impossible for him to farm mushrooms. The cool atmosphere and the sealed plastic room constituted the ideal conditions for Robin to ripen cheese on site.

- ↑ 5.0 5.1 Ferme du Temple is a small dairy and potatoe farm located up the city of Visé, Belgium. Since a few years, it engaged in direct sales from producers to consumers with a variety of dairy products from their farm, as well as local products (honey, sirop, apple juice) from farms nearby. By bike, it takes 15km from Heer neighborhood to reach the farm, then 15km to reach the Jan Van Eyck Academie and store milk before to process it.

- ↑ 6.0 6.1 6.2 6.3 6.4 Danisco CHOOZIT MA4002 LYO 5 DCU.

- ↑ 7.0 7.1 7.2 Texel Penicillium Roqueforti PRB18

- ↑ 8.0 8.1 "Since 2007, the dairy goat farm of the Noelmans-Peters family has been located in the middle between the beautiful St. Hubertuskerk in Membruggen and the Molenbeemd nature reserve." (from Riemst website) The farm located in Flanders, Belgium, hosts ±400 Saanen goats. By bike, it takes 16km from Heer neighborhood to reach the farm, then 14km to reach the Jan Van Eyck Academie and store milk before to process it.

- ↑ 9.0 9.1 Danisco CHOOZIT Penicilium Candidum SAM3 (against Mucor).

- ↑ Danisco CHOOZIT MVA.

- ↑ 11.0 11.1 11.2 Danisco CHOOZIT PLA mixed rind blend.

- ↑ Mucor often are an unwanted genus of white hairy molds, also known as “cats hair” in the cheese industry — although they can be part of the rind formation for some farm cheeses like St Nectaire.

- ↑ Danisco CHOOZIT Geotrichum candidum GEO17.

- ↑ 14.0 14.1 Launay farm is located at 42km from Paris, in the French Vexin, next to the town of Nesle-la-Vallée. This conventional dairy farm is run by two brothers, Eric and Romain Chevalier: with a capacity of 45 cows, the building has grown to 90 cows during the last years. This milk is sourced from Laiterie de la Chapelle, Paris.